News

What is cermet insert

What Is Cermet Insert?

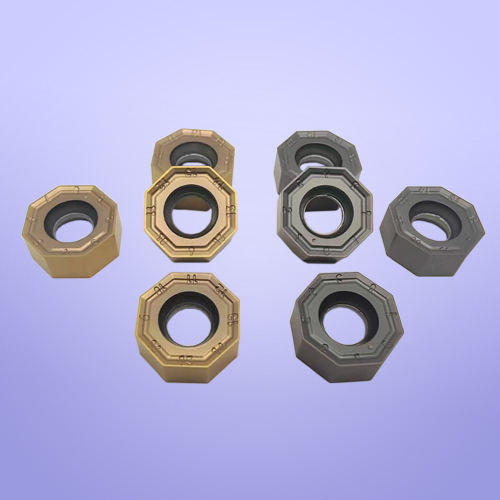

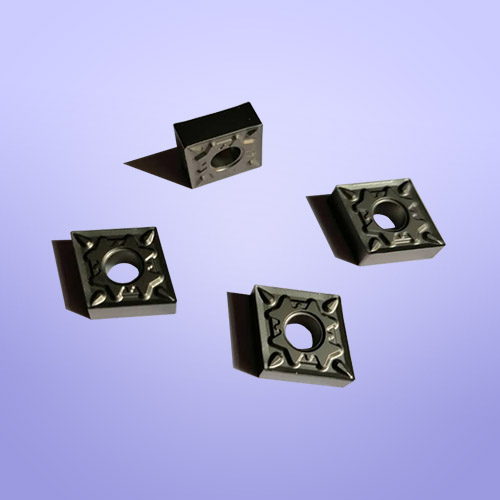

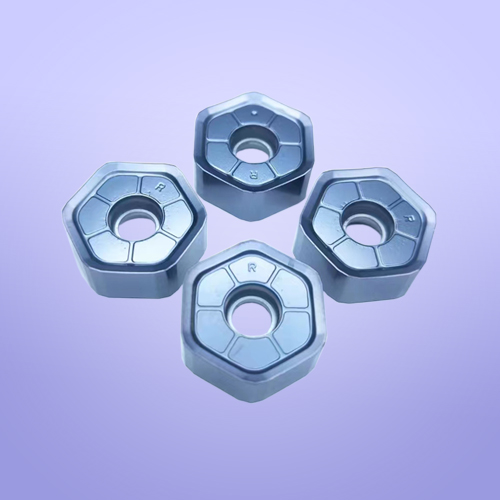

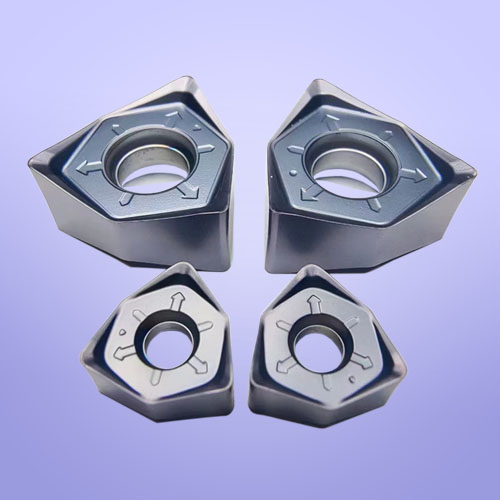

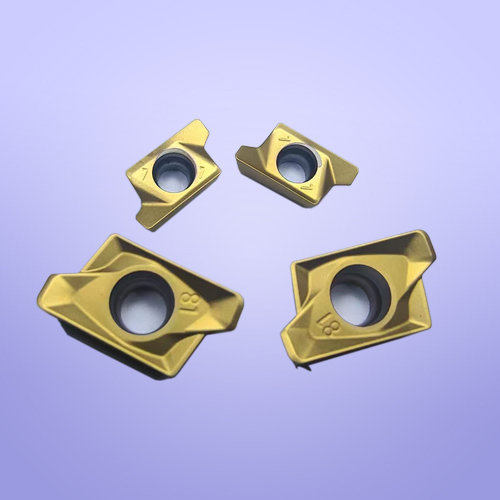

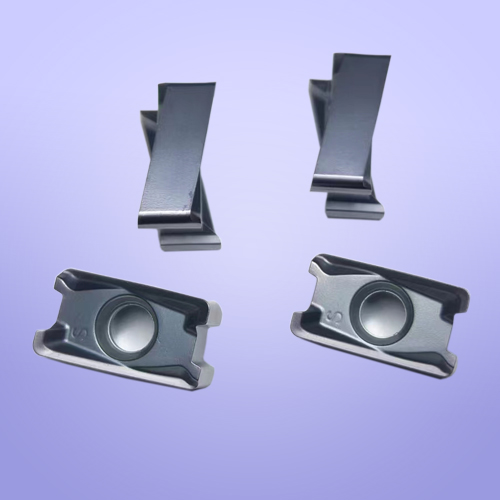

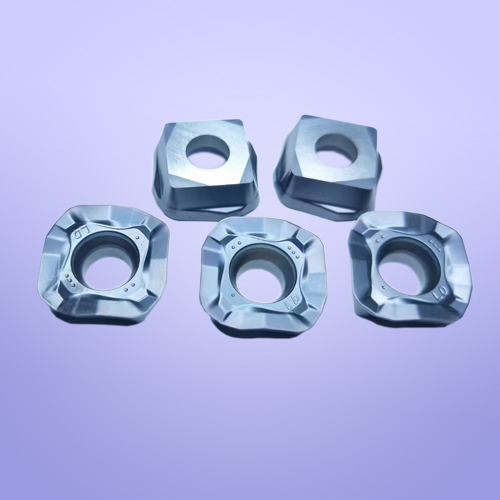

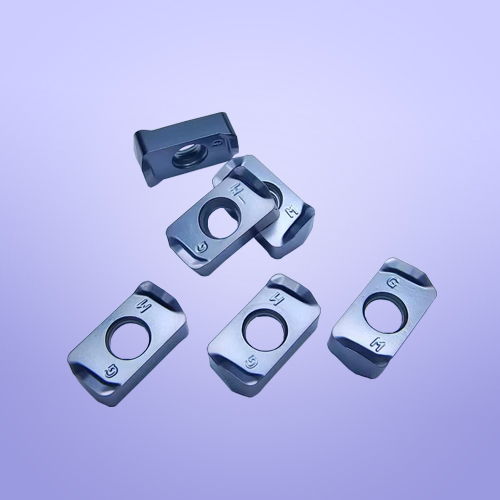

Cermet Insert

Cermet is a cutting material combining ceramics and metals. The result is a harder substrate than carbide, therefore more wear-resistant, and enables machining at higher cutting speeds. The downside is very low toughness.

What is cermet?

The word ceramic is a combination of cer and metal. It is mainly divided into two cermets, TiC-based and Ti(C,N)-based alloys. Ti(C,N)-based cermet is sometimes called cermet carbide or cemented carbide. Its hardness and heat resistance are close to ceramics, but its bending strength and fracture toughness are higher than ceramics.

History of cermet insert?

The research on cermet materials originally originated in 1929, focusing on the TiC base, and related literature reports focused on the study of the binder phase. The traditional WC-Co cemented carbide is made by the combination of ceramic hard phase WC and metallic Co. It can also be called a cermet. A large part of the research on new cermets aims to replace WC-Co Cemented carbide, which can save strategically significant W and Co, which has very important practical significance for resource-poor countries. Ti(C,N)-based cermets appeared in the European metal processing industry in the late 1970s; appeared in Japan in the early 1980s; China developed a variety of Ti(C,N) during the Eighth Five-Year Plan period. )-Based cermet tools.

Applications of cermet inserts

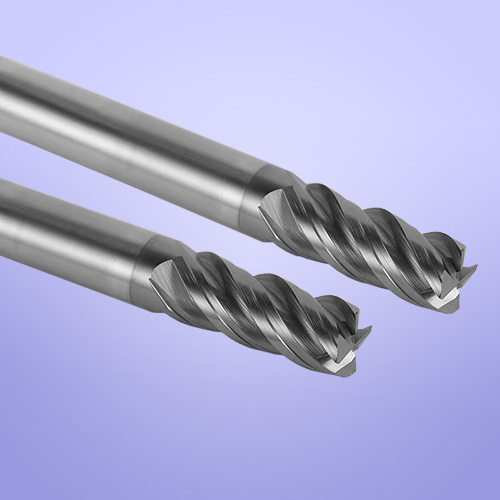

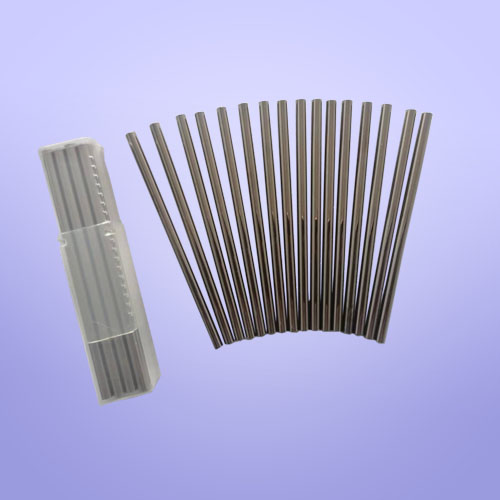

Ti(C,N)-based cermet material has the advantages of low density, greenhouse hardness and high temperature hardness better than WC-based cemented carbide, good chemical stability, oxidation resistance and corrosion resistance, and good wear resistance and thermal conductivity. It can replace WC Base cemented carbide and TiC-based cermets are widely used in the processing of ordinary carbon steel, alloy steel and cast iron, as well as the precision milling and precision turning of steel parts.The application range of cermet tools fills the gap in the field of high-speed finishing and semi-finishing between WC-based cemented carbide and ceramic tools. It is not only suitable for high-speed finishing, but also for semi-finishing and intermittent cutting of steel, and cutting High speed, good surface quality and long tool life. Ti (C, N)-based cermets can also be used to make micro-indexable inserts for precision boring, precision hole machining, and turning instead of grinding. Ti(C,N)-based cermet has low density, good friction performance, stable high temperature strength and excellent acid and alkali corrosion resistance, making it suitable for high temperature parts of engines, sealing rings in petroleum and chemical fiber industries And valves and various measuring tools.

What is the development prospect of cermet insert?

The current limitation on the large-scale application of Ti(C,N)-based cermet composites in high-end cutting tools and hot extrusion dies is mainly due to the insufficient strength and toughness of the materials. Increase the development of ultra-fine grain structure cermet composite materials with uniform structure, develop China’s ultra-fine grain hard tool materials and hot extrusion die materials, and promote the update of China’s high-end hard tools and hot extrusion die materials Both the replacement and technological progress are of great significance.

RELATED NEWS

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Doris

E-mail: info@zzcermet.com

Add: No.1 of Longxin international building, No.255 of Tongxia Road,Shi Feng District, Zhuzhou Hunan Province,China