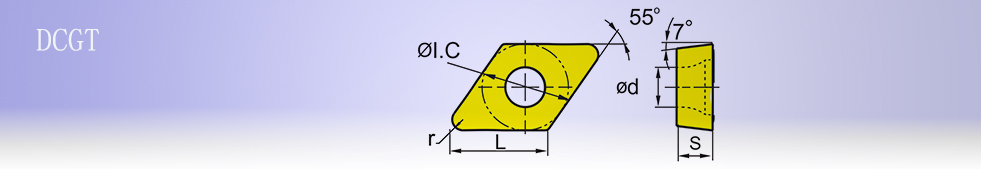

Cermet Indexable Turning Inserts DCGT

Good impact toughness

Smooth Chip removal

Wide range of application

Processing object:Semi-Finishing of steel,low-alloy steel

High Quality Cermet insert DCGT series turning inserts manufacturer.With Special strength and toughness.OEM and ODM acceptable.Unmarked or customized marking available.The common types are always in stock,Free sample available.

|

Type |

Basic Dimension |

Grade |

||||||

| L |

ΦI.C |

S |

Φd |

r | ZZX | ZZC | ZZB | |

|

DCGT Series |

7.8 | 6.35 | 2.38 | 2.8 | 0.2 |

◐ |

△ |

□ |

| 7.8 | 6.35 | 2.38 | 2.8 | 0.4 |

◐ |

△ |

□ |

|

| 11.6 | 9.525 | 3.97 | 4.4 | 0.2 |

◐ |

△ |

□ |

|

| 11.6 | 9.525 | 3.97 | 4.4 | 0.4 |

◐ |

△ |

□ |

|

TiCN based cermet, improved chemical stability and wear-resistant, with sharp cutting edge and chip-breaker, can get good surface no matter under high speed or low speed,suitable for steel, stainless steel and cast iron finishing.

|

Grade |

ISO |

Density (g/cm³) |

Hardness (HRA) |

TRS(N/mm²) |

Referenced Grade |

Application |

|

ZZC |

P05-P20 |

6.6-6.8 |

92.5 |

≥1600 |

TN60,NS530,CT3000 |

Suitable for turning,be able to do finishing&semi-finishing for bearing.Carbon steel.low alloy steel. |

|

ZZX |

P10-P30 |

6.8-7.1 |

92.5 |

≥2000 |

NX2525,NS740 |

Suitable for milling machining,excellent wear resistance,be able to do finishing&semi-finishing for hardness material. |

|

ZZB |

P10-P40 |

6.9-7.2 |

91 |

≥2800 |

|

Mainly suitable for the production of bar,mold materials,semi-finishing milling tools. |

|

ZZM |

|

6.4-6.6 |

90 |

≥2400 |

|

Suitable for corrosion-resistant mold material and high impact performance requirements of wear-resistant parts. |

|

ZZN |

|

6.0-6.2 |

93 |

≥1500 |

|

Suitable for corrosion-resistant wear-resistant parts. |

Advantage:

1.More wear-resistance than tungsten carbide,hardness reach to HRA90-HRA93.

2.More abrasive resistance than tungsten carbide.

3.More better surface finish of the work-piece.

4.More environmentally friendly without cutting fluid when processing.

5.Professional cermet inserts factory since 2014.

6.Professional and strict inspection by trained workers.

7.Professional Technical Engineer with 30 years experience to solve all kinds of problems encountered in processing for customers.

8.Adequate stock to ensure fast delivery.

At our compay, we care about our customers as much as we care about life. If you have any questions, please do not hesitate to contact our sales by info@zzcermet.com.Our sales are standing by for you from Monday through Saturday.

Carbide inserts

Milling inserts

Carbide cutting tools

Carbide endmill

End mill

Carbide end mill

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Doris

E-mail: info@zzcermet.com

Add: No.1 of Longxin international building, No.255 of Tongxia Road,Shi Feng District, Zhuzhou Hunan Province,China